Uncategorized

Unlocking Soap Science

While I was still working as a technical sales representative for a medical device company in the dental field, I was visiting one of my clients who knew I had a side hustle of making soap and skincare products. After visiting her doctor for her annual check-up, my client was so excited to tell me her doctor instructed her to start using saponified soap. Hmmm…..

With widened eyes I replied, ‘well, gee, I can help you with that!’

The reality is ALL soaps are saponified. I wasn’t sure why her doctor would recommend saponified soap. Even liquid soap is saponified.

WHAT IS SOAPONIFICATION?

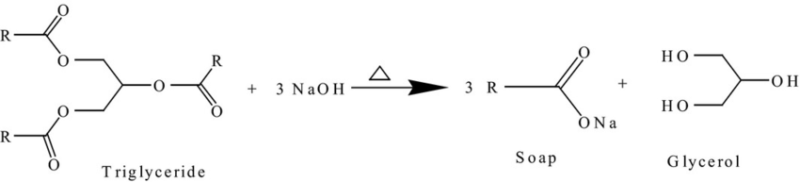

Saponification is combining vegetable oils and/or animal fats with lye. The end result is soap (fatty acid salts and glycerol). Below is the chemical reaction where R represents fatty acids, O is oxygen, and sodium hydroxide (NaOH) plus water (H20) is lye. Following the arrow to the right is the fatty acid salts (soap) and glycerol (glycerin).

Saponification is an acid-base reaction converting fats/lipids (acid) with lye (sodium hydroxide in water) into soaps. As a graduate student taking pharmaceutical biochemistry, I spent three weeks studying acid-base reactions. Who knew it would become such an important event in my life.

HOW SAPONIFICATION WORKS

At Luxe Body Worx we use the cold processed method of making soap. Mixing sodium hydroxide into water creates an exothermic (heat generating) reaction (around 240 degrees F). Plant oils and butters are melted to a nice homogeneous mixture and once cooled to just above room temperature, essential oils are added and sometimes certain botanicals if they will be throughout the whole soap. Then when the right temperature is reached by both oils and lye, we mix them. The chemical reaction begins. Stirring and blending speeds the reaction along. The batter (as it’s often called) goes from a translucent solution to an opaque one. Looking for trace (when the surface can support a drizzle from the spatula) is when pouring can begin.

The soap batter is poured into molds and tops are textured. The molds are placed in a draft free environment and kept warm to facilitate the continuing of saponification. The molds will continue to put off heat for hours as the chemical reaction continues. 24 hours later the molds are cooled and the soap is ready for unmolding. At this point saponification is complete.

Once unmolded soap loaves are allowed to adjust to room temperature for another 24 hours before cutting. Afterward, the soap bars are allowed to cure and harden for six weeks before they are wrapped, labeled, and sent to you.

I have a couple short videos on my YouTube channel showing the process of soap making. If interested, they are here and here.

Glycerin is a natural byproduct of soap making. It’s magnificent! It’s a natural cleansing and antimicrobial agent and a humectant (water drawing). At Luxe Body Worx, we created a perfect soap formula that offers wonderful glide, is long lasting, and won’t dry out your skin. We have over forty different scent varieties! Please explore our collection! Surely, there’s one even for the very discerning!![]()